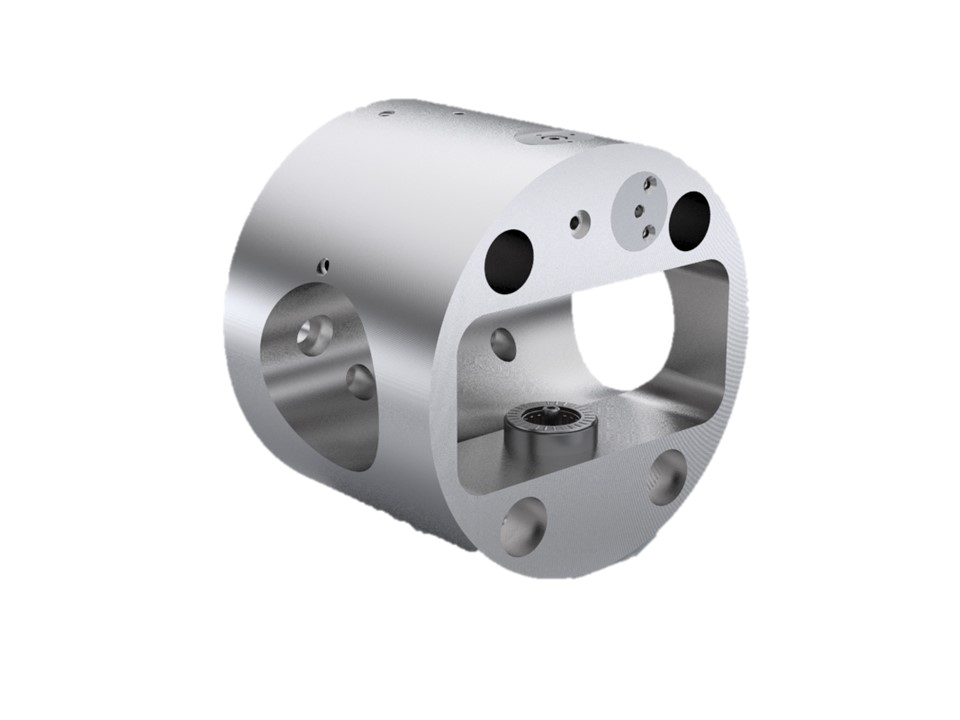

HSR Automatic Indexing Chuck

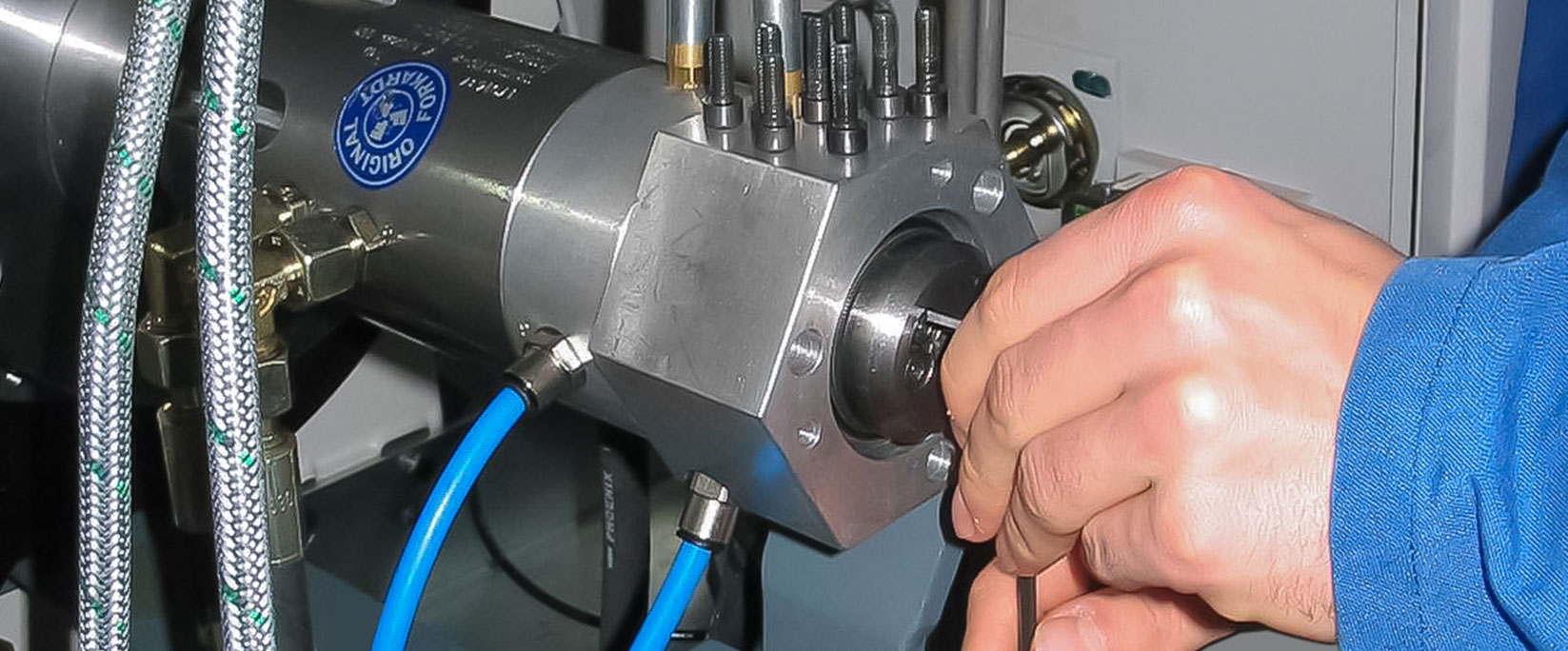

The Forkardt Index Chuck Type HSR performs clamping, indexing, locking and unclamping of the jaws by the use of integral hydraulic cylinders. Oil is fed to the various cylinders via a multiple oil supply system mounted on the spindle end and a pipe bundle running through the spindle bore. The automatic indexing chuck is hydraulically controlled via two four way solenoid valves. In cases where there is a requirement for proximity scanning, the indexing mechanism cover can be designed according to customer requirements.

The index chuck clamps unilaterally via the clamping position of the lower chaw. Two hydraulically operated opposed flanges working in sequence index and lock the fulcrum pin. The angular position of the jaws is matched to the number of component axes and maintained with a high degree of accuracy. The rough component part is automatically centered by the jaws, prisms and the concentric clamping pressure. The successive machining cycle produces equal shapes with minimum out of balance and dimensional accuracy.

The completed indexing cycle is acknowledged via an additional oil channel which operates a control cylinder that actuates a limit switch or can be actuated via proximity control scanning. This processes allows the appropriate program sequence of the tools in relation to the workpiece which then allows a controller to be assigned to multiple machines while maintaining sufficient safety and control.

| Technical Data | ||||||

| Type / Size | HSR 200 | HSR 225 | HSR 275 | HSR 350 | HSR 400 | |

| O.D. Diameter | [mm] | 200 | 225 | 275 | 350 | 400 |

| Chuck Mounting | [mm] | 185 | 185 | 210 | 290 | 290 |

| Max Operating Pressure | Fmax. [daN] | 2300 | 3300 | 4600 | 6800 | 6800 |

| Max Clamping Force | Fsp max. [daN] | 2300 | 3300 | 6800 | 6800 | 9400 |

| Max Speed | RPM [minu02c9¹] | 4200 | 3800 | 3400 | 2200 | 2000 |

| Weight | [Kg] | 20 | 26 | 49 | 91 | 115 |